Among the many considerations to make when getting an ERP system, perhaps the biggest one is whether you want to opt for a generic, off-the-shelf solution that you’ll customize to your company’s requirements or a solution that is specifically designed for your industry. Over the course of this blog, we’ll explore the differences between industry-specific and generic ERP systems and talk about the things you should consider during the selection process.

Generic ERP Systems

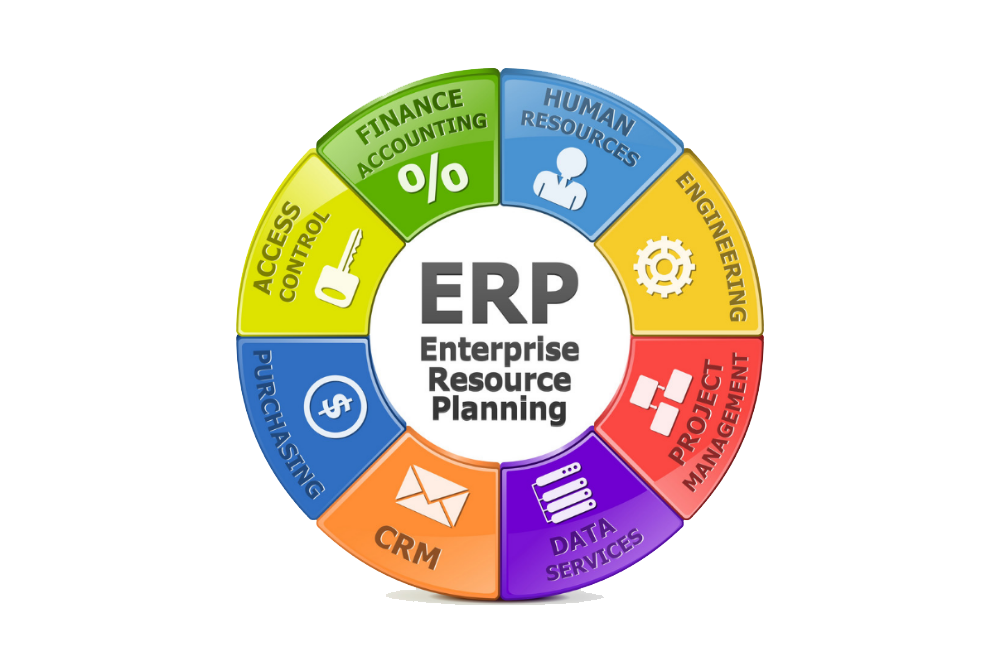

Let’s start off by defining “generic ERP,” as the term might have evoked some negative connotations with a few readers. Many people consider generic ERPs to be off-the-shelf solutions that are limited in terms of flexibility. Designed to cater to the needs of all types of ERP industries, they typically offer little room for customization. However, one major advantage of generic ERP solutions is their affordability. For the purpose of this blog post, we’ll assume generic ERPs to be the polar opposites of vertical-specific solutions.

Industry Specific ERP

Industry-specific ERP systems are solutions that have been specifically designed to cater to the needs of a particular industry. An example of this is manufacturing ERPs. Contrary to being a jack-of-all-trades, these systems are much more far-reaching in terms of functionalities when it comes to the specific requirements of an industry. As it is, an ERP system is a vastly complicated and multi-layered concept. In addition to the sizeable challenge of connecting, streamlining, and automating a plethora of business processes, they also have to count on the industry regulations and the specifics of different countries. Consequently, ERP providers who specialize in a specific industry enjoy a competitive advantage in terms of the efficiency, functionality, and implementation speed of their offered solutions.

Since specialization is becoming a rising trend in the business landscape, the requirements of companies are becoming more unique. This has resulted in a rising demand for purpose-designed ERP modules to fulfill the particular needs of industries. Industry-specific ERP systems offer a more holistic solution. In addition to enhancing basic business processes, they provide functionality that solely focuses on a specific vertical. This has been especially beneficial for process manufacturers as it has provided them with greater control in a wide range of areas. These include tracking of raw materials, quality control, formulation of recipes, recalls, product safety, and management of regulations and compliance.

Therefore, it’s little wonder that 67% of ERP-using businesses are opting for solutions that offer more industry-specific functionality, according to a study by Mint Jutras, a Boston-based analyst firm.

Is Micro-Vertical ERP the Next Step?

Some ERP providers are going a step further by developing solutions that focus on micro-verticals. Micro-verticals signify breaking down the processes of a particular industry into even smaller categories. For instance, although a soda manufacturer and a frozen food company are both categorized as a food and beverage industry, they have different options in terms of ERP offerings.

ERP requirements can vastly differ even in companies that belong to the same industry. For instance, Italian automotive giants Fiat Chrysler utilize a central IT policy that dictates that all of the corporation’s subsidiaries should use the SAP ERP system. However, Ferrari, which was previously owned by Fiat Chrysler, chose to opt for the Infor LN ERP solution to enhance the management of its internal processes. This is because Ferrari has a vastly different business model compared to its former parent company. Unlike Fiat Chrysler, Ferrari sells supercars that are highly customized to the buyer’s specifications. Consequently, Ferrari requires a much more flexible and agile system compared to manufacturers of mass-market consumer automobiles.

Major Things to Consider During the ERP Selection Process

ERP system selection can be a very overwhelming process. Thanks to our vast experience in the industry, we’ve learned that certain guidelines can be of great help in simplifying this complicated process. Here are some useful ERP selection tips:

- Figure out your enterprise’s strengths and weaknesses – identify the areas and the business processes that you aim to enhance with a new ERP solution.

- Decide on the areas of your business that you want to be automated first. This will get you fast results without having to wait for the whole system to be implemented.

- Devise an evaluation criterion for your new ERP solution. The primary factors you should consider are:

- The Price of the solution in regards to the features and customizability it offers.

- The Flexibility the system offers. The system should be future-proof to a certain extent. This means that the new solution should be adaptable to the future growth of your business.

- The Functionality offered by the platform. Implementing a system that offers a wide range of functionalities generally takes time. So this depends upon whether time is of the essence for your company.

A leading specialist in Sage and QuickBooks cloud hosting services, gotomyerp can assist you in finding an ERP solution that is perfectly suited to the requirements of your enterprise. Get in touch with us today.